Cyber Security News Aggregator

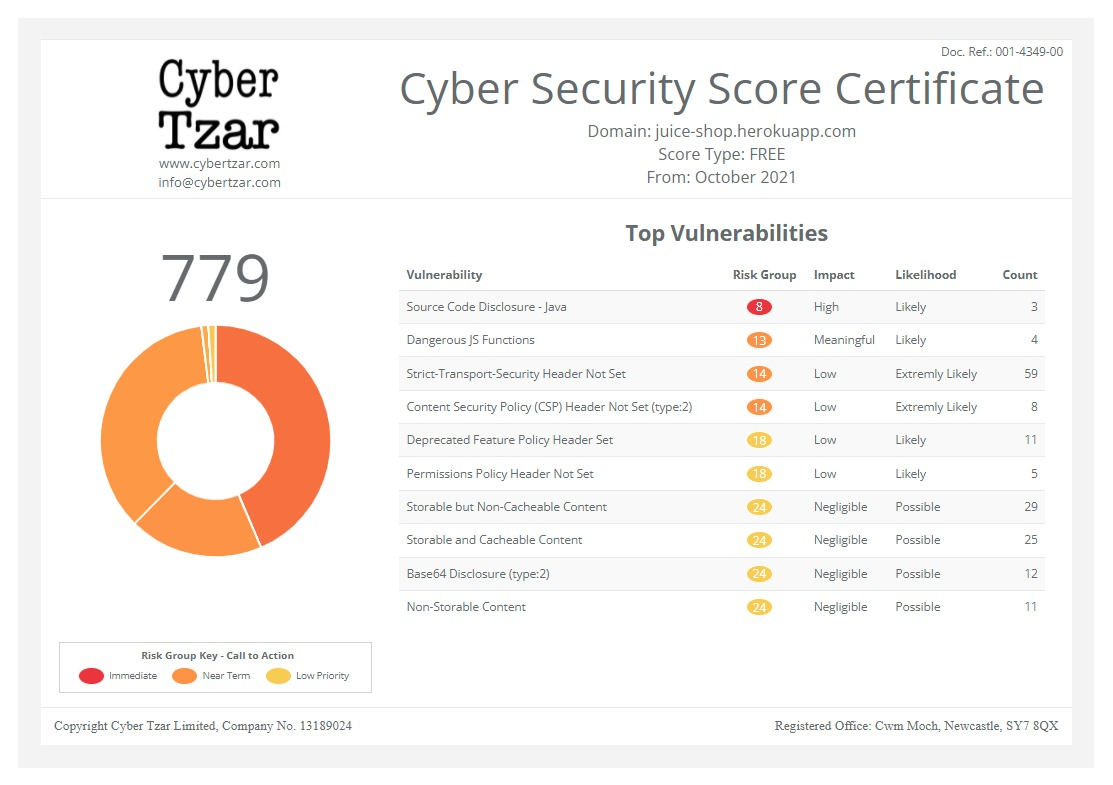

.Cyber Tzar

provide acyber security risk management

platform; including automated penetration tests and risk assesments culminating in a "cyber risk score" out of 1,000, just like a credit score.Konica Minolta extends thermal imaging range

published on 2023-02-20 11:26:11 UTC by Simon FinlayContent:

Konica Minolta has extended its thermal imaging monitoring portfolio with the new MOBOTIX p71 Thermal ECO camera and new MOBOTIX Advanced Radiometry App.

The thermal imaging monitoring operates in three main areas: early fire detection (or even detecting the risk before flames arise); quality assurance and process optimisation; and 24/7 security in object and perimeter protection – all whilst being fully GDPR-compliant.

Shintaro Inoue, Head of Video Solution Service at Konica Minolta Business Solutions Europe said: ” These latest additions to the thermal imaging monitoring portfolio provide important benefits in terms of fire prevention safety, process optimisation, and security, to deliver exceptional features, reliability, and tangible ROI. With the march towards ever greater systems integration and digital transformation, this is a solution which will further support businesses in a rapidly evolving world.”

DETAILS

The Thermal ECO technology was already available as a module for the MOBOTIX M73 and S74 multi-lens systems. The new MOBOTIX p71 Thermal ECO camera now offers affordable thermal image monitoring as a single-lens camera for indoor use with an intelligent camera base and app capability. With its wide 105° angle of view, Thermal ECO technology ideally suits object or perimeter protection applications against intruders and burglars. This applies in absolute darkness and for particular data protection-compliant requirements (DSGVO), as it detects intruders but does not show any details for personal identification (protecting privacy).

The new MOBOTIX Advanced Radiometry App extends the possibilities of the thermal radiometry 7-camera series (TR) by detecting critical heat or fire sources with up to twenty measurement areas, each of which you can configure individually. This allows users to include several emission values (radiation from surfaces of different materials) or distances in a single camera image, making the application even more precise and flexible.

Fire protection

Overheating in storage, production, or other facilities can quickly lead to fire and flames that endanger people and property, causing financial loss, operational downtime, reputational damage, and harm to the environment. Sophisticated fire alarms and other security systems are unlikely to warn of heat risks that indicate an impending fire. Thermal cameras on the other hand, can identify fire and overheating risks much sooner than traditional systems — before flames and smoke develop — by detecting hotspots where a fire might start.

The proactive heat detection and fire prevention MOBOTIX thermal camera technology is certified by three internationally recognised institutions: VdS (German Loss Prevention Association), EN 54-10 (EU standard), and CNPP (French National Center for Prevention and Protection). Here, MOBOTIX Thermal systems were comprehensively tested and certified concerning their ability to detect fires as early as possible. The certificates allow integration into existing fire alarm systems. In addition to comprehensive all-around fire protection, the systems meet insurance companies’ requirements and building regulations.

Quality assurance and process optimisation

Numerous production and processing operations place particular demands on the temperature of raw materials, intermediate products, or the end product. In addition, the smooth operation of machinery is mandatory. Downtimes cost money.

Konica Minolta’s MOBOTIX thermal systems enable preventative maintenance and can trigger a variety of different functions and subsequent processes as soon as tolerance limits are exceeded or undershot. This ensures product quality. MOBOTIX thermal cameras automatically detect and report critical temperature deviations of any kind – whether hot, warm, or cold.

Konica Minolta’s comprehensive MOBOTIX Raw Data Support works with all the AI (artificial intelligence) applications of the respective system. The intelligent thermal systems can be connected to industrial systems such as SCADA or MQTT via interfaces (machine-to-machine communication).

This integration then allows the merging of central data, the analysis of which can provide essential starting points for making effective decisions and optimising processes as a basis for savings and revenue increases.

https://securityjournaluk.com/konica-minolta-extends-thermal-imaging-range/?utm_source=rss&utm_medium=rss&utm_campaign=konica-minolta-extends-thermal-imaging-range

Published: 2023 02 20 11:26:11

Received: 2023 02 20 11:45:49

Feed: Security Journal UK

Source: Security Journal UK

Category: Security

Topic: Security

Views: 4