Cyber Security News Aggregator

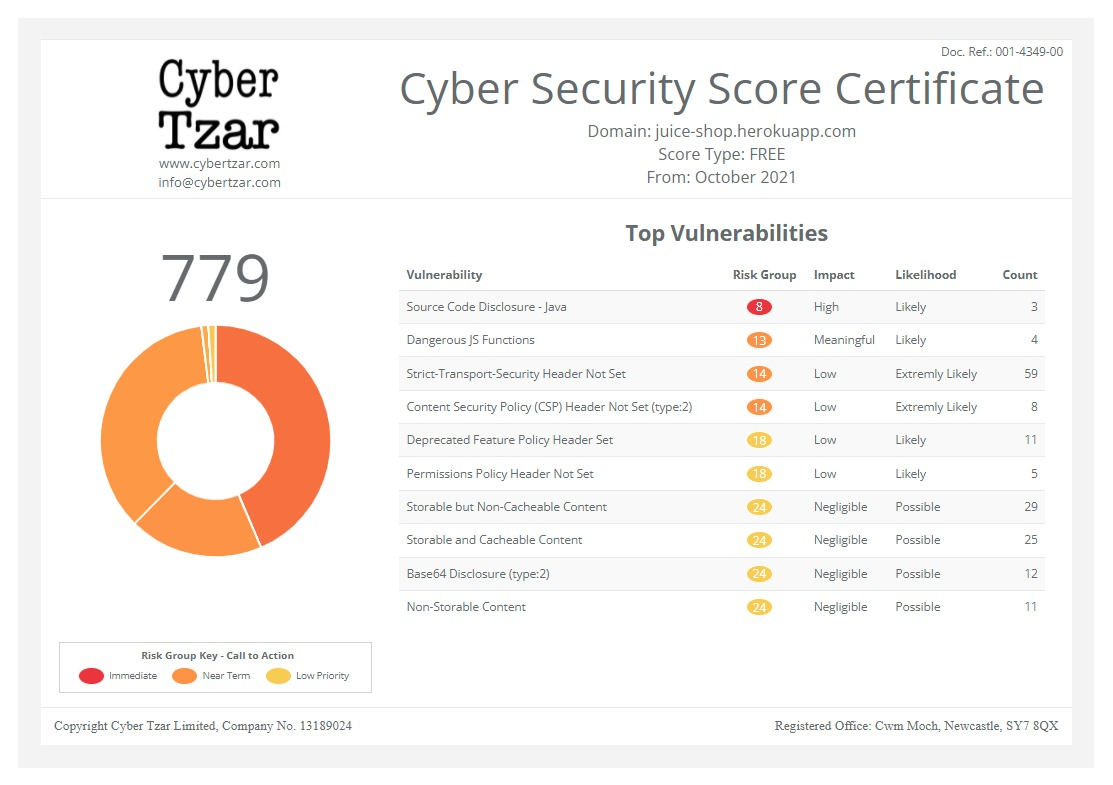

.Cyber Tzar

provide acyber security risk management

platform; including automated penetration tests and risk assesments culminating in a "cyber risk score" out of 1,000, just like a credit score.Hardware considerations for warehouses

published on 2024-04-12 07:45:00 UTC by James HumphreysContent:

Andrew Syms, business development manager at HOPPE (UK), outlines some tips for choosing architectural ironmongery for warehouse projects.

The boom in online shopping we’ve experienced in recent years shows no signs of slowing down.

In 2024, e-commerce is expected to constitute 37.5% of the UK’s retail market.

To accommodate this, more and more warehouses are appearing up and down the country, peppering the skyline with the gradient blue exteriors we’ve come to recognise.

Analysis from the Office for National Statistics shows that the number of business premises being used for transport, logistics, and warehousing in the UK has almost doubled in the last decade.

The amount of business premises classified as “freight transport by road” and “postal and courier activities” increased by 114% and 147%, respectively, between 2011 and 2021.

By its very nature warehouse work is transient, meaning it’s common for the workforces within them to change on a regular basis.

Couple this with plenty of large open spaces, and it can be difficult to keep track of people.

This raises security concerns, and when you consider that 20% of all recorded crime in the UK accounts for offences against businesses, it’s important to take precautions.

Security in warehouses can take several forms, from employing qualified security professionals to provide manned on-site services, to alarm systems and CCTV cameras, but there are also ways to incorporate security into the building itself rather than retrospective measures once the building is built.

Think about who can access the warehouse and how.

The building should always be secure, and employees who are allowed access should be equipped with the necessary means to enter.

Locks for steel doors

Steel fire doors are becoming more common in warehouses which is why it’s important to ensure locks have been tested appropriately.

For example, ARRONE locks within the 900 series are BS EN 12209 performance tested, BS EN 1634-1 fire tested and assessed for use on 240-min steel fire doors.

When it comes to security for general office space, meeting rooms, or even storerooms, a mortice sashlock is a good solution. It’s possible to specify a mortice sashlock which has two bolts.

In this case, one is the latch bolt, so when the door is shut into the frame it will stay closed – regardless of whether it is locked or not – and the other is a dead bolt that can be locked for added security.

A mortice latch is usually used on internal non-locking doors and is popular in communal office spaces. It is operated by using a lever handle or knob and is designed to keep doors closed but not locked.

This makes it convenient for office staff to enter and exit the area.

A higher security measure may be required in areas where expensive items are stored or where staff personnel files are kept.

Mortice nightlatches will automatically lock when the door closes, and they require a key to access from the outside.

This not only makes them ideal for external doors but also for internal doors including storage cupboards or restricted areas in public buildings.

Outside access devices

There is an ongoing need for panic and emergency exit doors on commercial buildings to also be accessible from the outside.

For this, an outside access device (OAD) is used.

Ideal for addressing fire safety requirements without compromising security, OADs can be locked to stop manual attacks to the device and prevent illegal entry to the building.

In many cases, doors that are part of the emergency exit route could also be used as entrances into a building, but the hardware requirements are different for such uses.

The outside access devices from ARRONE, including the AR885, AR8805 and AR8806, are designed to overcome these issues and make use of existing doors to improve access into the building.

Providing limited access

To help protect a warehouse from unwanted visitors, mechanical push button locks are ideal.

They work by setting a code, which is shared with every worker who’s allowed access to that particular area of the building.

This is especially useful for back offices, places where sensitive information is stored, and general storage spaces.

If someone leaves the business, then the code can be easily changed straight away so that they can no longer gain access.

A mortice lock is also recommended for additional security.

Don’t forget fire doors

As well as security, those specifying products for warehouses need to place equal emphasis on safety and accessibility.

One important thing to consider is fire safety.

The Regulatory Reform (Fire Safety) Order 2005 applies to most non-domestic premises and businesses, including factories, warehouses and storage facilities.

This means that the designated Responsible Person is – as the name suggests – responsible for fire safety in the business.

This includes carrying out regular fire risk assessments (FRA).

From 1 October 2023, the Building Safety Act 2022 came into effect with Section 156 amending the Regulatory Reform (Fire Safety) Order 2005.

It requires all fire risk assessments and their findings to be recorded, irrespective of the number of employees or whether there is a licence in force.

The government’s ‘fire safety risk assessment: factories and warehouses’, updated last year, is a guide covering large and small factories, manufacturing warehouses, storage warehouses and factories with warehouses.

It states that you should check every month that all fire doors are in good working order, are closing correctly, and that the frames and seals are intact.

The guide also includes details on where fire doors should be located as well as helpful checklists on what to look for when carrying out a fire risk assessment in relation to fire doors and escape routes.

Non-insulated steel fire doors are a common choice particularly in industrial and commercial environments, as they are durable, long lasting and require little maintenance.

It’s important to note that any door closer fitted to an un-insulated steel fire door must be proven in application on both the fire and non-fire side of the door.

Products that will be used on fire doors must also have a CE mark to demonstrate compliance to the relevant standards.

To achieve this, a product must demonstrate successful tests for both performance and fire.

Perfecting emergency exit hardware

In an emergency, the evacuation of a building needs to be as simple as possible. It is essential that building users can open doors easily so that everyone can leave safely.

In the case of warehouses, emergency exit hardware (rather than panic hardware) is used as building users are familiar with exit routes and the building is not accessible to the public.

Devices for emergency exits could be a simple push pad type device or a lever handle that operates a mortice escape lock or nightlatch.

Futureproofing warehouses

Ensuring a warehouse is secure is not only important for the financial viability of a business but also for the safety of employees.

If a warehouse can be easily broken into or vandalised, it can lead to staff members feeling vulnerable.

This article was originally published in the April Edition of Security Journal United Kingdom. To read your FREE digital edition, click here.

https://securityjournaluk.com/hardware-considerations-for-warehouses/

Published: 2024 04 12 07:45:00

Received: 2024 04 12 07:46:55

Feed: Security Journal UK

Source: Security Journal UK

Category: Security

Topic: Security

Views: 14