Cyber Security News Aggregator

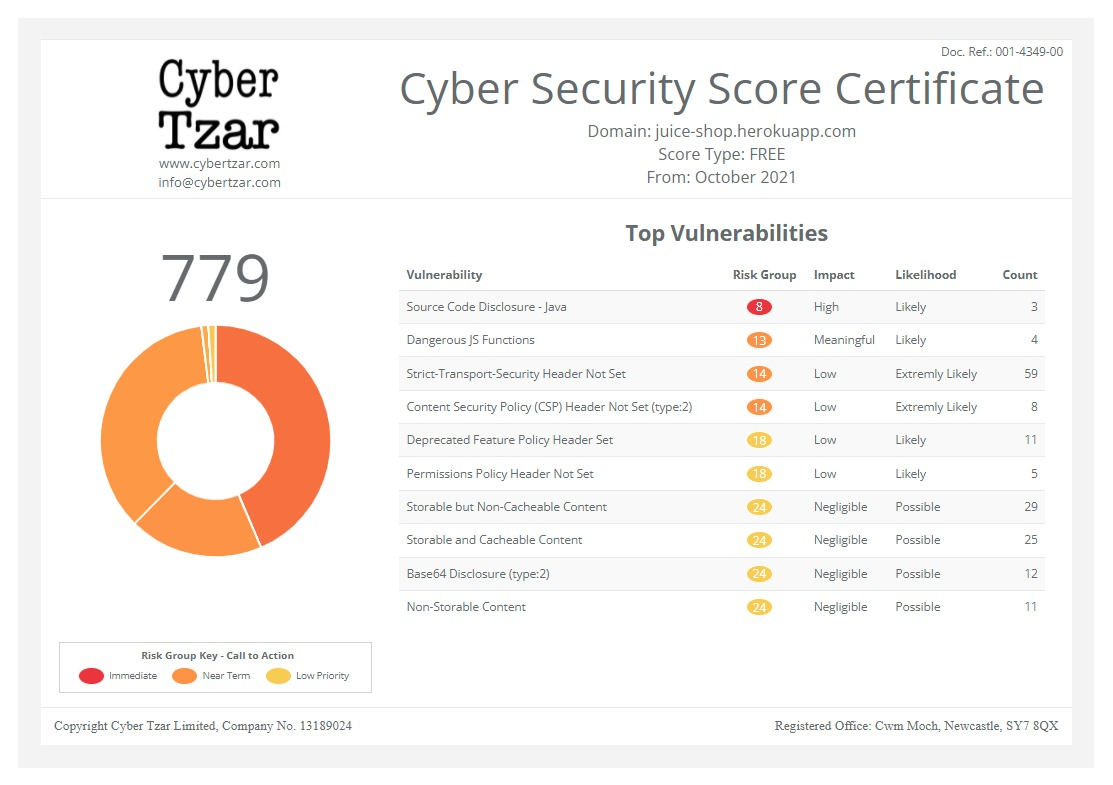

.Cyber Tzar

provide acyber security risk management

platform; including automated penetration tests and risk assesments culminating in a "cyber risk score" out of 1,000, just like a credit score.Gunnebo Entrance Control enhances maintenance offering

published on 2024-11-26 09:38:25 UTC by James HumphreysContent:

Gunnebo Entrance Control has improved its preventative maintenance offering, as a connected service to maximise equipment uptime, extend asset value and support sustainable operations.

EntraServe Connect enables organisations across high-demand environments, such as offices, stadia and critical infrastructure sites, to keep their systems performing with minimal interruption.

Through real-time remote monitoring, Gunnebo’s specialist teams can detect potential issues early, allowing quick corrective action before issues arise.

According to the company, this approach maintains uptime and extends the value of each entrance control solutions by reducing the need for extensive on-site maintenance and costly unexpected repairs.

Gunnebo to ensure secure access

“Our clients rely on Gunnebo Entrance Control to ensure secure, efficient access,” said Emilia Taskinen – VP of Customer Service and Recurring Revenue of Gunnebo Entrance Control.

“The launch of EntraServe Connect takes us to the next level of service offering.

“This connected service allows us to deliver smarter, faster maintenance and effectively prevent downtime, providing an elevated level of reliability, sustainability, scalability and peace of mind to grow with our customers.”

Longer-lasting equipment and reduced repair requirements contribute to lower lifecycle costs and a smaller environmental footprint, aligning with sustainable operational goals.

With EntraServe Connect, Gunnebo Entrance Control provides continuous visibility into the health of each customer’s equipment.

Advanced analytics deliver actionable insights that enable predictive maintenance, further extending equipment longevity and reducing the frequency of in-person service visits.

Proactive tools

“As businesses across the globe face increasing legislative demands for efficiency and data management, EntraServe Connect offers the proactive tools required to keep operations running smoothly and compliantly,” added Taskinen.

“And by combining remote monitoring with advanced diagnostics, we’re empowering our customers to take control of their equipment health, reduce operational disruptions and extend the lifespan of their assets – all while contributing to a greener future.”

https://securityjournaluk.com/gunnebo-enhances-maintenance-offering/

Published: 2024 11 26 09:38:25

Received: 2024 11 27 11:23:56

Feed: Security Journal UK

Source: Security Journal UK

Category: Security

Topic: Security

Views: 18