Cyber Security News Aggregator

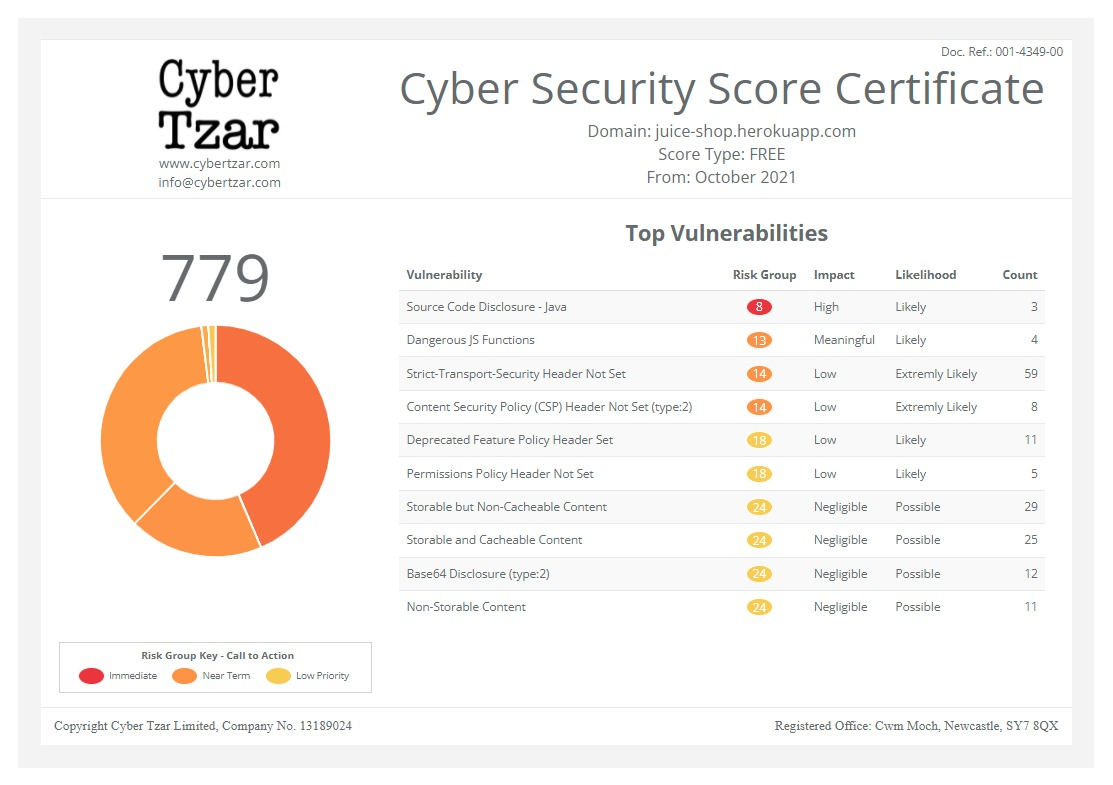

.Cyber Tzar

provide acyber security risk management

platform; including automated penetration tests and risk assesments culminating in a "cyber risk score" out of 1,000, just like a credit score.Creating a smarter, safer and greener world with Axis

published on 2025-03-25 08:31:00 UTC by James HumphreysContent:

Kieran Byrne, Architecture & Engineering Lead at Axis Communications, explores how choosing energy-efficient cameras can reduce near term costs while also supporting longer term environmental commitments.

Energy bills continue to drive up the cost of doing business.

The intensity of the energy crisis may have lessened, but it is still ongoing – even businesses with capped price plans face bills 40% higher in 2025 than they did in early 2022.

The end of the UK’s Energy Bill Discount Scheme has exacerbated the issue, leaving many businesses struggling to manage rising expenses.

But reducing energy consumption is not just a means of maintaining profitability; it is a vital part of meeting environmental goals and sustainability strategies.

With initiatives such as the Circular Economy Action Plan (CEAP) and the Science-Based Targets initiative (SBTi), businesses are encouraged to take action.

A well-planned, long-term procurement strategy can reduce environmental impact, help lower energy costs and emphasise emissions reduction across entire supply chains without sacrificing effectiveness.

This begins by prioritising non-negotiable, continuously running equipment, with surveillance technology a key focus.

Unlocking power savings in surveillance

Energy consumption of surveillance systems is both a significant sustainability concern and a major cost factor.

Even minor variations in power usage per device become substantial when multiplied across the considerable number of devices employed as part of a typical surveillance network.

Consider this: running a 5W camera costs approximately £12.54 annually per unit, while a 10W camera doubles the cost to £25.07.

For a network of 1,000 cameras, this results in a £62,700 vs. £125,350 cost difference over five years.

As far as sustainability initiatives are concerned, the same network of 1,000 10W cameras would require 1,948 trees to offset its carbon footprint; at 5W, this drops to 974 trees.

But even beyond immediate cost savings, it is essential to evaluate the total cost of ownership (TCO) of the system over its lifetime.

All too often, buying decisions are based on the initial cost of system hardware and installation, but neglect the running expenses of a system which could last from five to over 20 years.

Upfront costs of a security system account for just 30% of the total cost, with 70% of the expense coming after the system has been installed in the form of maintenance, energy consumption and eventual decommissioning.

Improved efficiency without performance loss

In many cases, energy and cost savings may also be possible – without sacrificing performance – if a business can reduce the volume of hardware in a surveillance network.

Modern advancements in security technology mean many traditionally server-dependent workloads can be offloaded to on-board processors, working to manage tasks like analytics on the network edge.

The higher resolution of newer network cameras offers an opportunity for a single unit to replace multiple older cameras.

This might take the form of a wide-angle, 4K sensor, its view broken out into areas of interest for security personnel. It might involve a PTZ camera, using object analytics to focus on the most important activities.

It could even mean using a 180-degree dome camera, de-warping and splitting its view in-camera to deliver multiple clear images directly to a VMS.

And clever use of cameras can lead to sustainability improvements and savings elsewhere.

Lighting is a heavy contributor to rising business energy costs, even as the switch to more efficient LED solutions continues.

But does the level of illumination need to be what it is? High-performance camera sensors can operate in far lower light conditions than was once the case, producing full-colour, high-resolution imagery without a requirement for bright lighting in unoccupied or peripheral areas.

Advancing sustainability activities is not about making sacrifices or diminishing performance in the name of the environment – it’s a case of making smart choices.

Power consumption and regulation

Energy-conscious decisions are about more than just reducing costs – they are increasingly vital for regulatory compliance.

Businesses must adhere to mandates such as the UK Energy Savings Opportunity Scheme or, in places like data centres, Energy Star certification.

Compliance not only helps to avoid penalties and legal issues, but it also helps to prepare organisations for the future.

A surveillance system might provide for a business for a decade or more; ideally it will match the environmental attitudes of the day when it reaches end-of-life.

The sustainability impact of security systems begins with their supply chains.

Every piece of hardware comes with an environmental footprint that includes raw material extraction, emissions from production, transportation and even storage.

To mitigate these impacts, businesses must seek accredited assurances of the provenance of all security equipment at the procurement stage.

Without such due diligence, purchasers risk inheriting the sustainability costs, and becoming indirect contributors to environmental harm.

Stepping up material sustainability

Regulations like REACH, RoHS and WEEE require businesses to keenly evaluate their material choices.

Some materials pose significant environmental and health concerns – Polyvinyl Chloride, or PVC, is a notable example. Its production is energy-intensive, and it contains hazardous chemicals.

In the event of a fire, burning PVC produces toxic chemicals; when doused with water, it releases hydrochloric acid.

PVC is often mixed with phthalates, known to carry significant health risks, as a softener.

These can leach from the PVC into the environment throughout its lifetime.

Although the use of certain phthalates is already restricted under REACH, and more currently sit on its authorised list for future restriction, official phthalate regulations currently apply only to a small subset of consumer products.

Official regulations do not include commercial or office installations, and there is no legal requirement for manufacturers of security equipment to use phthalate-free wiring, for example.

Given that more sustainable and environmentally friendly alternatives exist, the use of PVC and phthalates, as well as fire retardants like BFRs and CFRs, should be considered as largely obsolete.

If a manufacturer is not taking steps to reduce or eliminate the use of such chemicals, that may be contrary to the Environmental, Social and Governance (ESG) standards of its purchaser.

Fresh thinking for a better world

PVC or not, all fossil-based plastics have a sustainability cost attached to them which cannot ever be repaid. And as the world moves towards a circular economy, products must go beyond the goals set by WEEE.

Their packaging and components should be suitable for full recycling when they reach end of life, for example.

Post-consumer recycled plastics and bio alternatives can take the place of much virgin plastic.

And when a new-today system is decommissioned, the process should be as simple and clean as possible – particularly given that regulations will only tighten down the line.

In the end, reaching and supporting an ESG agenda is a question answered through partnership and planning.

Organisations are under incredible and immediate pressure to change, but to ensure that every system change offers a secure, long-lasting opportunity to create ongoing improvements they must think cleverly about the future.

Partnering with vendors that share a keen eye for sustainability, making a detailed map of one’s existing facilities to find every little improvement, and properly evaluating every change is the only way to ensure any system overhaul reaches its true potential.

Businesses face a difficult challenge today, and potentially a larger one in the near future, but a sustainability-first IP camera upgrade provides a long-term saving that makes for a smarter, safer, and greener world.

This article was originally published in the March 2025 Edition of Security Journal UK. To read your FREE digital edition, click here.

https://securityjournaluk.com/creating-a-smarter-safer-greener-world-axis/

Published: 2025 03 25 08:31:00

Received: 2025 03 25 08:41:03

Feed: Security Journal UK

Source: Security Journal UK

Category: Security

Topic: Security

Views: 20