Cyber Security News Aggregator

.Cyber Tzar

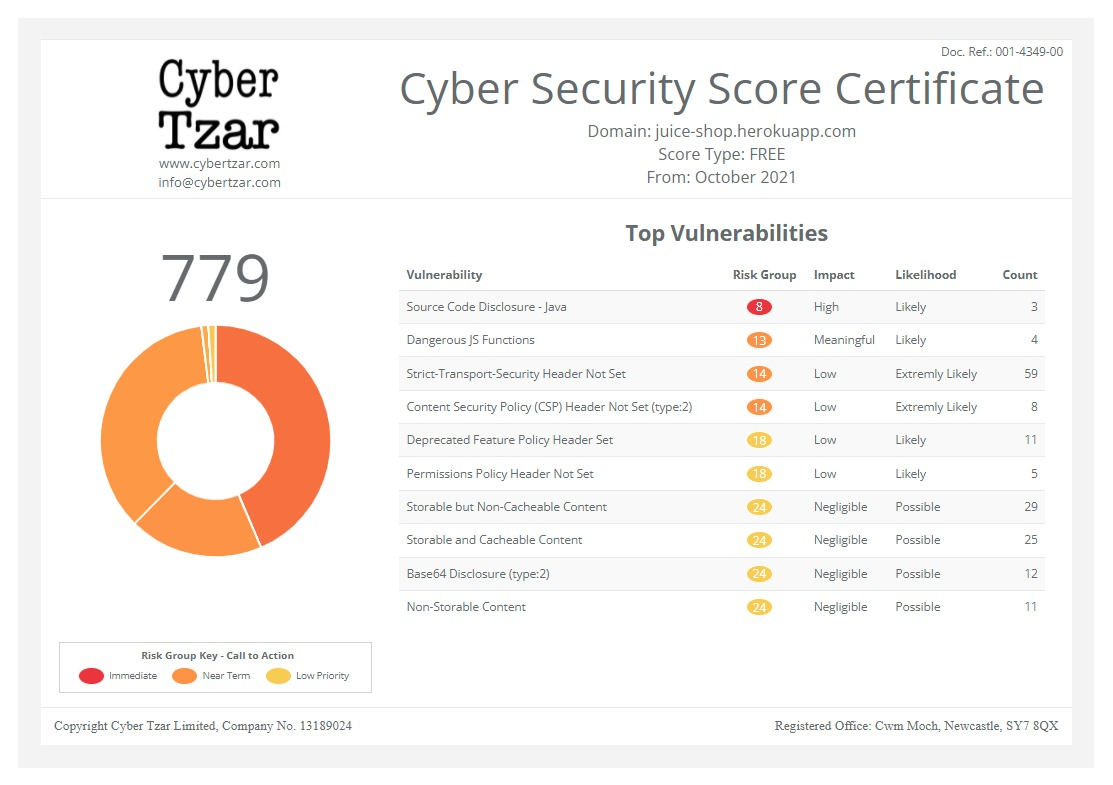

provide acyber security risk management

platform; including automated penetration tests and risk assesments culminating in a "cyber risk score" out of 1,000, just like a credit score.First Fence: Designed for strength and simplicity

published on 2025-04-21 07:30:00 UTC byContent:

Toby Roberts-Davies, Product and Marketing Manager at First Fence, discusses the need to upgrade from traditional perimeter protection solutions.

First Fence Ltd is a leading UK manufacturer of temporary and permanent fencing.

With seven depots across the UK and a fleet of over ninety vehicles, First Fence prioritises security and swift delivery for all fencing solutions.

A significant problem

It’s no secret that when thinking of temporary fencing, one typically envisions a Heras-style panel surrounding a construction site, secured with couplers and set in rubber base blocks.

This is considered a low-security fencing solution, but it serves a purpose as a means of demarcation from a safety perspective.

Manufacturers of temporary fencing often face the challenge of balancing commercial appeal with compliance to British Standard BS 1722 Part 18: “Performance Requirements for Free-Standing Temporary Steel Mesh Perimeter Fence Panels.” More often than not, price takes precedence over quality, leading to significant security vulnerabilities at construction site perimeters.

A recent survey by Churchill Support Services found that over 50% of trades people had experienced tool theft valued between £1,000 and £4,999, with 94% of stolen tools never recovered.

A major contributing factor to this is the ease of unauthorised site entry and the ability to access unattended tools.

The statistics on site break-ins are shocking.

We recognised that the market for a higher-security temporary fence was not being adequately catered for.

In response, First Fence developed RapidShield as a solution to this problem.

Improving site security

There are two approaches to site security: either rely on traditional site fencing and enhance it with Perimeter Intrusion Detection Systems (PIDS) or make it more difficult for intruders by increasing the physical security of the perimeter fence.

The RapidShield system is First Fence’s very first fully designed temporary fencing system to feature anti-climb mesh.

This mesh, known as 358, consists of apertures constructed from 4mm horizontal wires set at 12mm centres, creating daylight apertures of just 8mm—significantly reducing the ability to climb or scale it, hence the term ‘anti-climb mesh’.

However, the challenge for First Fence didn’t end there. To properly stabilise a temporary fence run, BS 1722 Part 18 recommends a triangular stabilisation formation, which requires two additional panels at the rear to enhance stability.

The downside of this is the amount of space required, and the additional stock needed to achieve a stable fence.

While kentledge blocks are an alternative, most solutions still require machinery such as telehandlers for installation.

Designed for strength and simplicity

For ease of installation, First Fence developed a fully folded base, allowing manually handled 50kg blocks to be lifted into place.

This results in lower deployment costs, eliminates the need for heavy machinery and offers a space-saving solution for hire companies.

Security is paramount, so RapidShield incorporates T40 torx fixings, renowned for their anti-tamper design, requiring a hollow bit that inserts into a male pin at the centre of the fixing head—preventing easy disassembly.

When designing a system intended for mass adoption, we knew it had to offer high security while remaining quick to deploy.

No one wants to use a temporary fence that takes three times as long to assemble.

To address this, the system uses a single type of fixing to secure the mesh to the posts, meaning installers only need one tool for the entire job.

Flexible gate solutions for changing site layouts

With a full range of vehicle and pedestrian gates, RapidShield also tackles the common issue of unauthorised vehicle access.

Site gates are typically installed using concrete and a dug-in hinge post. As site phases progress and entrances move—sometimes two, three, or even four times—new gate sets are often ordered for reinstallation.

Recognising this as an inefficient use of labour, materials and resources, First Fence designed the RapidShield gate range to be fully relocatable, leaving no physical trace once removed.

Additionally, because the ballast is positioned on the inside face of the gate, an intruder would already need to be inside the site before even attempting to dismantle it—further reducing security risks.

Enhancing perimeter protection

A common objective of site intruders is ‘urban exploration’ and the thrill of accessing ‘no-go zones’.

Traditional temporary fencing panels, at just 2 metres in height, with thin-gauge mesh prone to bending, provide ample footholds, making them an easy target for climbing.

To combat this, RapidShield is designed to accommodate a full range of mesh heights, including 358 anti-climb mesh up to 3.0 metres high, significantly increasing site security.

When launching this system, we anticipated concerns over wind loading due to the increased solidity of the mesh.

To address this, we conducted wind load testing and now offer certifications tailored to the UK’s average wind speeds for all three infill types and four height variations.

The future of site security

In conclusion, when it comes to enhancing site security—particularly in blind spots where detection is limited, and response times are slow—there is now a new solution provider.

The traditional temporary fence panel will always have a place in the industry, as there is an ongoing demand for basic demarcation fencing for safety purposes.

However, with increasing pressure to secure sites and prevent unauthorised access, the time has come to upgrade to a more effective solution.

This article was originally published in the April 2025 Edition of Security Journal UK. To read your FREE digital edition, click here.

https://securityjournaluk.com/first-fence-designed-for-strength-simplicity/

Published: 2025 04 21 07:30:00

Received: 2025 04 23 03:22:40

Feed: Security Journal UK

Source: Security Journal UK

Category: Security

Topic: Security

Views: 21