Cyber Security News Aggregator

.Cyber Tzar

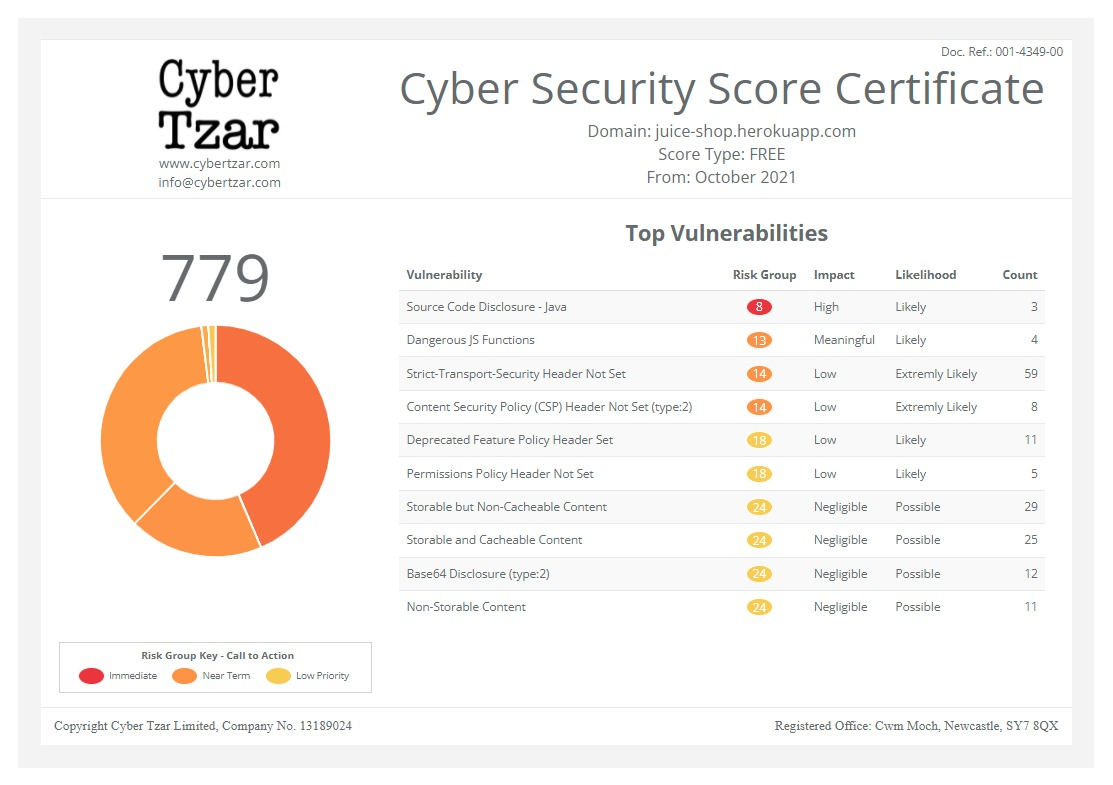

provide acyber security risk management

platform; including automated penetration tests and risk assesments culminating in a "cyber risk score" out of 1,000, just like a credit score.Abloy UK: Leading innovation and safety in access control

published on 2025-09-08 14:22:03 UTC by Millie Marshall LoughranContent:

Pat Jefferies, Commercial Director, Abloy UK discusses his pivotal role in establishing and expanding the Abloy Academy to champion training, compliance and life safety in door access systems.

Can you tell us about your role at Abloy UK?

My role at Abloy UK started in 1994 when I joined as a Sales Representative.

I progressed to Regional Sales Manager for the South of England with a strong focus on the mechanical side of the business.

After four years I became National Sales Manager and shortly after I progressed to Academy Director.

Now my position stands, as it has been for the past 14 years, as Commercial Director.

One of the biggest transformations I have seen during my career, at Abloy UK, was in 2007 when we launched the Academy at ABLOY concept in Watford.

It was at this time that I became the Director of the Academy and so the company and I began to develop our educational message and teach individuals about our products and why we need to maintain certain compliance standards to provide life safety.

The development at the academy was unprecedented and so was Abloy UK’s success and so in 2022 we split the Academy into two.

This is when the Digital Access Solutions (DAS) Academy was launched.

At this second academy, students learn about the products and services that Abloy delivers.

Individuals also learn how to install products properly to support the quality and innovation of the company’s products.

My role is key in educating individuals about how to provide life safety and strike a balance between the end user functionality and compliance, ensuring that we never compromise the ability to escape or compromise the fire compartmentalisation of the building.

As a business we are always looking to provide security from the secure side and escape from the inside of any door; this aspect of our business has enabled us to provide a dynamic lockdown system that benefits the end user.

In 2007 at the ABLOY Academy, we were teaching delegates about the new European Standards that were in force but at that stage were considered as ‘Best Practice’.

In 2013, with the introduction of Construction Product Regulation (CPR), life safety standards for Fire Door applications and Escape door applications became mandatory.

When we left the European Union 2020, the previous CPR became defunct and so compliance standards changed again. The UK retained the EU CPR as a domestic law but amended it creating the UK CPR covering UK only.

Whilst compliance was developing, so was my career.

It was obvious at the time that we needed to split the leadership role for the academies, and so I continued as the Commercial Director looking after the academy at Abloy UK.

I passed the Technical and Product Director role to Pip Courcoux.

This transition was great timing as our product ranges were changing.

My personal expertise tends to fall within mechanical locking and electromechanical locking but stops with wiring, and Abloy UK had moved on.

We now have the Aperio range, the CLIQ Electro-mechanical product range and one big thing with this range is that it is all wireless technology or embedded software.

And that is arguably a step too far for me, so it was perfect timing to split the business, allowing me to concentrate on two things: Education within the market and making sure that our technical side was still in place for our traditional products.

The split allowed us to divide and conquer and utilise each of our skills to enhance our objectives.

In what ways does Abloy UK’s commitment to building trust safety and security influence product development and customer relationship?

I think that the backbone of the business is that we are a trusted advisor.

Sometimes, we are faced with a solution that Abloy UK cannot necessarily provide and yet we will always point our clients in the right direction.

Our goal is to always maintain security; we never compromise the ability to escape or compromise the buildings need for compartmentalisation; and that goal is maintained whether we can provide the end user with the solution ourselves or not.

The two big drivers in our business are identifying the door that a client needs to secure and then understanding what that door needs to do.

We have mastered this ability, if the door is a red door it needs to have fire tested solution and if the door is a green door, it needs escape tested solutions.

Compartmentalisation and the ability to escape is at the cornerstone of what we do.

It is all about life safety, it is about having the ability to get out of a building when you need to, without compromising security and ensuring that a building will be safe in the event of a fire or where escape is necessary.

Our biggest concerns everyday are an individual’s ability to escape and the compartmentalisation in a building.

How do you ensure compliance and control without sacrificing safety at Abloy UK?

There’s always a fine balance and there are solutions that can be used now.

The reality is that we should never be blocking an escape door, but sometimes there is a requirement to do so.

We do now have a new set of rules, in BS EN 13637 it describes how you would escape through an escape door if that door is electrically blocked.

But that is not something you never take lightly.

The first question is, why do you need to do that? Is there another way? Can we avoid using a BS EN13637 solution?

So almost, an anti-sales message, but that is the message that we install in our teams daily, because, quite honestly, we should never be blocking an escape door.

And what we need to do is understand the rationale, the reasons why and look and see if there is another way of achieving the same objectives.

How do you support your customers and partners, including providing advice on which access management system to use?

The Academy at Abloy has been critical in supporting not only students but also customers, partners and end users.

The Academy teaches students how to specify said door and ensure that door is dressed correctly for life safety.

This academy leads people to the correct solution for any given scenario.

On the other hand, the DAS Academy empowers the distributor so that they can fit the correct support program and service said product throughout its life.

All whilst driving that compliance message to ensure that people’s lives are safe when they’re in said building.

Can you tell me more about Abloy UK’s training program and why this outreach is important to the company?

As well as my position as Commercial Director, I am also a UK technical representative for EN 14846.

As a company we invest time, effort and money that helps to develop European / British and TS (technical standards through trade organisations) to ensure that we have got these life safety principles in place.

We then convert that message into – what do we need to do?

The Abloy UK training program has arguably driven standards around the Door hardware standards European Norms and BS British Standards.

At Abloy UK we have a slide – ABLOY 6 door types.

It was written in June 2013 just in time for the changes in the Construction’s Product Regulation, where we identified six different door types.

These six door types are as follows: Convenience door; emergency escape door; panic escape door; fire door, non-escape; emergency escape and fire door and panic door and fire door.

These six different door types have also been adopted by other bodies.

The NSI are now using the same template within NCP 109, to identify the different door types to identify the door and ensure that the electric locking solution is compliant.

Given Abloy UK’s rich heritage in premium door locking systems, how does the company ensure continuous innovation to meet evolving security needs and technological advancements?

We are part of ASSA ABLOY – Abloy is based in a city called Joensuu in Finland.

The majority of our development is done in Finland, but the research is completed globally.

So as a business, we try to keep at the forefront of changes, developments, needs and requirements in the industry and that is continually fed back to our factory in Joensuu.

However, the UK has made lots of minor changes and driven development programs within the factory based upon the experience that we get in the marketplace.

I think it’s more about market intelligence, it’s about feedback, keeping up industry trends and requirements and feeding that back to our Research and Development team to develop those new solutions for a challenging and changing market.

This article was originally published in the September edition of Security Journal UK. To read your FREE digital edition, click here.

https://securityjournaluk.com/abloy-uk-innovation-safety-access-control/

Published: 2025 09 08 14:22:03

Received: 2025 09 09 01:23:28

Feed: Security Journal UK

Source: Security Journal UK

Category: Security

Topic: Security

Views: 11