Cyber Security News Aggregator

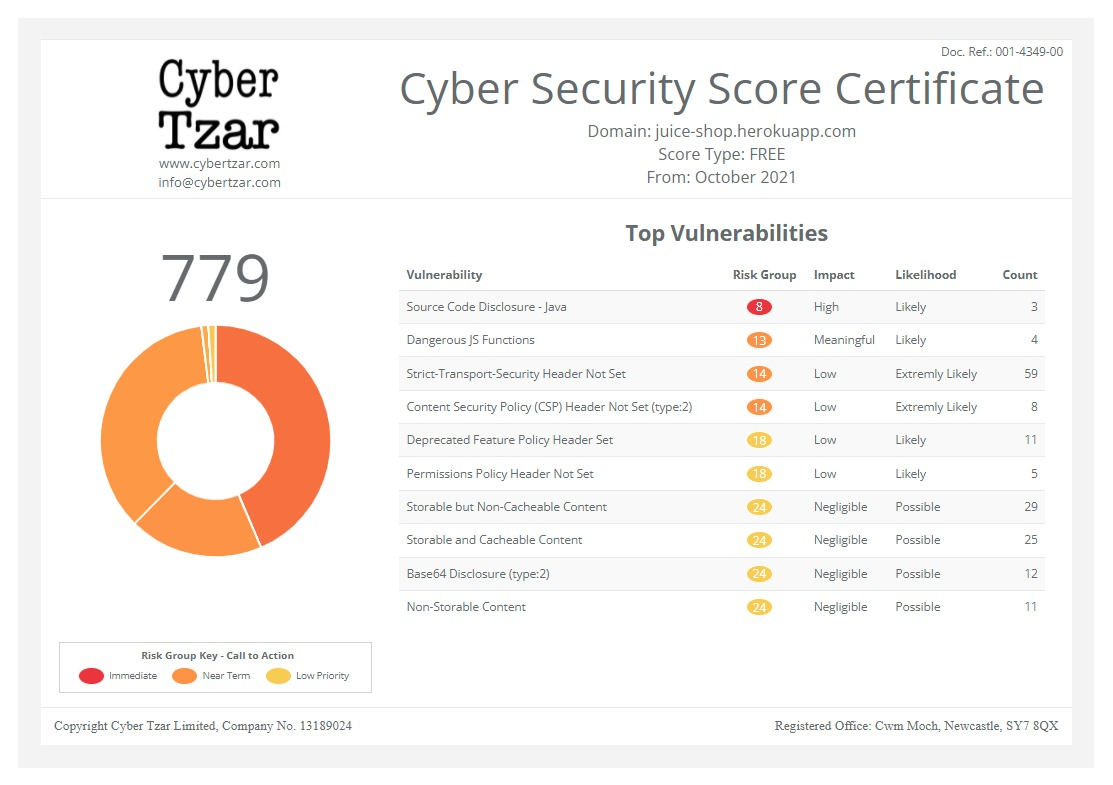

.Cyber Tzar

provide acyber security risk management

platform; including automated penetration tests and risk assesments culminating in a "cyber risk score" out of 1,000, just like a credit score.It’s just a fence, until it isn’t: Physical security challenges

published on 2025-09-09 16:16:15 UTC by Millie Marshall LoughranContent:

First Fence discusses how two panels that appear identical in construction diverge fundamentally when tested – standard mesh delivers basic integrity, while LPS 1175-rated systems are engineered to guarantee quantifiable ‘delay’.

Physical deterrents

In a world of ever-evolving security challenges, the line between a simple boundary marker and a genuine physical deterrent has never been more critical.

This brings us to a question we are often asked: “What is the real, tangible difference between your standard mesh fencing and your security-rated LPS 1175 version?”

It’s an excellent and vital question.

At first glance, looking at two almost identical mesh panels side by side, you’d be hard-pressed to spot the distinction.

The real difference, however, lies far beyond what the eye can see.

It is forged in the rigorous processes, exhaustive testing and exacting standards demanded by the Loss Prevention Certification Board (LPCB) for any product permitted to bear its mark.

First Fence: A commitment to quality

Toby Roberts-Davies, Product & Marketing Manager, First Fence explains: “As a business, our commitment to quality is absolute.

“Everything we do is geared around our ISO 9001 accreditation and the constant improvement of our processes.

“But the audit and certification for security-rated products takes this to another level entirely.

“It moves beyond quality management into validated performance, giving security professionals like you the cast-iron guarantee that what we promise is precisely what you get.”

To truly understand the value, we must delve into what LPS 1175 represents.

Developed by the LPCB, part of the world-renowned Building Research Establishment (BRE), Loss Prevention Standard 1175 was created to provide a single, reliable benchmark for the performance of physical security products.

It removes the guesswork and ambiguity for specifiers and end-users, creating a common language for resistance against forced entry.

Its current iteration, Issue 8, is continually updated to reflect the changing tools and tactics used by intruders.

A demanding certification process

The certification process is famously demanding.

A product isn’t just assessed; it is physically attacked by a team of highly trained experts who know exactly how to exploit potential weaknesses.

They use a specific toolkit against a strict time limit.

Crucially, the clock only runs when a tool is physically in contact with the fence.

This means a one-minute “tool time” test can often take five to ten minutes in real-time, simulating an intense and focused attack.

The standard is layered, with security ratings corresponding to the toolkit used and the time the product can resist it.

First Fence entered the high-security market in 2023 with its industry-recognised ProFence mesh and PaliFence palisade ranges, certified to LPS 1175 SR1 (A1).

This rating confirms the fence can defeat an opportunist attacker using small, concealable tools (Toolkit A) like screwdrivers, knives and pliers for over a minute.

While higher ratings like SR2 (B3) defend against more determined attacks using tools like bolt cutters and SR3 (C5) adds battery-powered tools to the mix, the SR1 rating is critical for deterring the most common threat: The casual opportunist.

When measuring success against the security triangle – detect, delay and respond – our certified ranges provide a validated and guaranteed ‘delay’.

This isn’t a vague hope; it’s a proven window of time, giving on-site response teams a critical advantage.

So, what goes on behind the scenes to maintain this standard?

While we can’t give all our secrets away, the integrity of the system begins with our material register.

Once a product line is certified, it becomes a ‘golden sample’.

It can only be manufactured from components specified in that exact configuration – from wire gauge and weld integrity to coating thickness.

These components are sourced from an exclusive list of approved suppliers, where we meticulously track their material batches and monitor performance.

This ensures the product installed on your site has the identical genetic makeup to the one that withstood the official LPCB attack.

The next crucial step is a watertight stock segregation plan.

Across our eight depots nationwide, it’s vital that all fencing components – many of which look identical to the naked eye – are stored to prevent any mix-ups.

This is more than just painted lines on the floor; it involves rigorous staff training and digital stock systems that flag LPS 1175 products, creating an unbroken chain of custody from fabrication to delivery.

Finally, after the components are produced and all tolerances are checked, our central distribution centre runs a second-stage quality control process. Every high-security item is visually inspected before despatch.

Any product that doesn’t meet our exacting standards is quarantined, triggering a root-cause analysis to correct and prevent recurrence.

Rober-Davies adds: “This is the final checkpoint and it’s non-negotiable for our customers.

“If a flaw has somehow slipped through the net during fabrication, this second line of quality control ensures it never reaches a customer’s site.

“It’s the ultimate reassurance of our unwavering commitment to the integrity of the LPS 1175 badge.”

About

First Fence Ltd is a prominent British fencing specialist founded in 2010, based in Swadlincote, South Derbyshire.

Since its inception, the company has rapidly emerged as one of the UK’s leading suppliers of security and temporary fencing, as well as traffic management and access solutions.

What sets First Fence apart is its proactive approach to customer service and innovation.

They were among the first in the industry to launch a fully operational e‑commerce website, streamlining the ordering process and improving transparency – at a time when many competitors lagged behind in digital services.

Their commitment extends to logistics, with a fleet of vehicles – ranging from 3.5-tonne vans to articulated lorries – ensuring same‑day, next‑day and express deliveries across the UK and into Europe.

From initially specialising in temporary fencing for construction sites, First Fence swiftly expanded into permanent and high‑security fencing.

In recent years, they’ve introduced advanced systems such as the ProFence SR1, which holds an A1 (SR1) rating under the stringent LPS 1175 Loss Prevention Standard – a testament to their dedication to certified and reliable security solutions.

Their network now includes depots in Bristol, Tipton, Glasgow, Essex and Nottingham, in addition to the Swadlincote HQ, ensuring rapid distribution and robust stock availability.

Recent investments further illustrate their ambition: In 2025, they added a new fleet of Sprinter vans, flatbeds and tractor units to enhance delivery efficiency and reduce environmental impact.

Moreover, they’ve formed a strategic partnership as the exclusive UK distributor for Wisniowski’s high‑quality gate systems, providing customers with comprehensive fencing and automated gate solutions.

This article was originally published in the September edition of Security Journal UK. To read your FREE digital edition, click here.

https://securityjournaluk.com/fence-physical-security-challenges/

Published: 2025 09 09 16:16:15

Received: 2025 09 10 03:22:35

Feed: Security Journal UK

Source: Security Journal UK

Category: Security

Topic: Security

Views: 10