Cyber Security News Aggregator

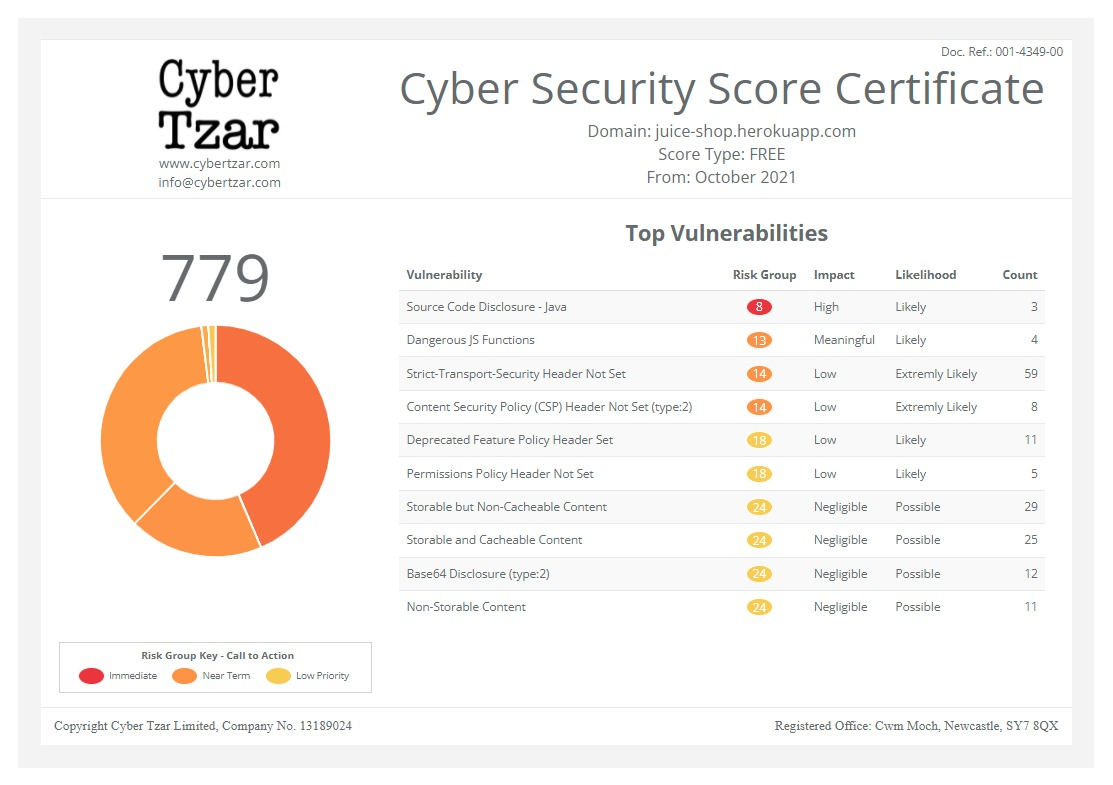

.Cyber Tzar

provide acyber security risk management

platform; including automated penetration tests and risk assesments culminating in a "cyber risk score" out of 1,000, just like a credit score.Aviation Security: Securing the skies

published on 2025-10-03 12:22:36 UTC by Millie Marshall LoughranContent:

Todd Research asserts that inflight supplies – from food and drink to service trolleys – must be rigorously screened using advanced technology to bolster aviation security without compromising efficiency.

Aviation Security

In aviation security, most attention has traditionally focused on passenger checkpoints.

Travellers are used to the familiar steps of removing shoes, scanning their carry-on bags and passing through body scanners.

Yet there is another, less visible area that is just as important: The screening of inflight supplies and catering.

While passengers encounter layers of aviation security designed to detect threats before boarding, aircraft themselves receive a vast stream of goods – food, beverages, duty-free items, linens and service equipment.

These items, loaded onto aircraft often minutes before departure, pass through supply chains that stretch across continents.

Extensive aviation security measures mitigate the risk of prohibited items being introduced into airline supplies, while these security measures reduce the risk existing methods are labour intensive and time consuming.

The challenge of screening every single item required: From every crate of juice, sealed box of meals, catering cart, trolley or overhead canister, this places extreme pressure on individuals working long hours to be both diligent and consistent.

In a system designed for speed, efficiency and passenger comfort, ensuring security without introducing crippling delays is an immense undertaking.

The hidden challenge of inflight supplies

Unlike passenger baggage, which passes directly from check-in to screening equipment, inflight supplies are sourced from a complex network of suppliers, warehouses, catering facilities and transport operators.

Each handoff introduces vulnerabilities. A single weak link, a supplier with insufficient controls, an unchecked employee, a facility without proper monitoring, can undermine the entire security framework.

The threat is real. Security reports often highlight aviation supply chains as tempting targets.

Risks include insiders with access, attempts at smuggling or hiding harmful devices in catering or service carts – issues security teams must prevent.

Unlike passengers, inflight supplies cannot be questioned or profiled; instead, they must be protected through clear processes, strong technology and careful checks.

Why screening supplies is different

Screening inflight supplies is very different from screening passengers or bags.

These supplies are large, come in many forms and are often perishable.

Unlike a standard suitcase, a catering cart may contain hundreds of individual items, many of which are sealed or temperature sensitive.

Screening must balance thoroughness with practicality.

Delays in catering deliveries can delay an aircraft; overly intrusive methods can compromise food safety and quality.

This tension between efficiency and security has driven innovation in supply-chain-focused screening solutions.

The need to balance speed with safety has encouraged new ways to screen supplies.

That’s why here at Todd Research we created the TR-STS.

Instead of focusing only on checks at the airport, regulators and industry partners now work together on a system that keeps goods protected throughout the entire journey – from the place goods are produced and packed, to the moment they are loaded onto the aircraft.

Technology as an enabler

Technology plays an essential role in making inflight supply screening both effective and efficient.

Airports are increasingly using advanced X-ray that can scan full catering trolleys and pallets without the need to take them apart.

On top of this, explosive trace detection (ETD) provides an extra layer of security, especially for random inspections or items considered high-risk.

Instead of relying only on traditional screening tools (like X-ray machines or metal detectors), the aviation industry is now using data-driven technologies (such as machine learning and advanced analytics) to improve security.

Modern X-ray machines used in aviation security are equipped with advanced features that go beyond basic image scanning.

They can save scan data for future review, enabling security teams to revisit and analyse images when needed for investigations or training.

In addition, colour enhancement technology is used to highlight different materials within a scanned item, making it easier for operators to distinguish between organic substances, metals and other materials.

These capabilities not only improve detection accuracy but also support better training, auditing and overall security effectiveness.

Human factors and insider risk

While technology is indispensable, the human factor remains central.

Insider threats – employees with legitimate access who exploit their position – pose some of the most serious risks to aviation supply chains.

Catering staff, drivers and ground handlers all play crucial roles in the flow of goods.

Ensuring that these individuals are thoroughly vetted, continuously monitored and supported with a strong security culture is essential.

Training programs that emphasise vigilance, reporting and adherence to security protocols are just as critical to aviation safety as X-ray machines.

A workforce that fully understands both the rationale and significance of security procedures serves as a proactive layer of defence, strengthening the system rather than presenting a potential weakness.

Efficiency versus security: Finding the balance

Airlines and airports operate in an environment where efficiency is non-negotiable.

A single delay in catering can ripple across flight schedules, affecting thousands of passengers.

At the same time, any compromise in security carries risks far greater than inconvenience.

The industry must therefore embrace models such as the TR-STS that integrate security seamlessly into operations.

Collaboration across the ecosystem

Securing inflight supplies is not the responsibility of a single stakeholder.

Airlines, airports, regulators, catering companies, security providers and technology vendors all play interdependent roles.

Effective security requires collaboration across this ecosystem.

Threat intelligence must flow quickly and securely between regulators and industry.

If one country or region develops an effective way of handling a security or safety issue, that knowledge should be shared globally so everyone can benefit.

Through the use of technologies such as the TR-STS, combined with proper training and human oversight, the aviation industry can strengthen a culture where all stakeholders share responsibility for safety and security.

Preparing for the future

As aviation continues to rebound from the shocks of the pandemic, the supply chain is becoming more global, more interconnected and more pressured to deliver at scale.

New threats – whether linked to crime, terrorism or global tensions – mean that inflight supply screening must keep developing at the same pace.

The future of aviation supply security will likely involve greater use of automation and data integration.

AI-driven screening can assist people by analysing scans and data, highlighting unusual patterns or items that may require closer attention, support human judgment and reduce the chance that suspicious items are overlooked.

At the same time, airlines face increasing pressure to be environmentally responsible.

Efforts to reduce leftover food, disposable items and packaging, while streamlining supply chains for faster and more efficient operations, can introduce new challenges for security.

For instance, less packaging can make tampering harder to detect and faster supply chains leave less time for thorough checks.

In this environment, the ability to quickly detect, respond to and recover from a breach – real or attempted – will define the effectiveness of aviation supply chain security.

Conclusion

Aviation security is often seen through the lens of passenger screening, but inflight supplies and catering represent a parallel frontier that demands equal attention.

The complexity and scale of these supply chains create unique challenges, but also opportunities to rethink how security is designed and implemented.

By combining regulatory frameworks, technological innovation, strong human factors and cross-industry collaboration, aviation stakeholders can secure this often-overlooked dimension of air travel.

The result will not only be safer skies, but also a more resilient, efficient and trusted aviation ecosystem.

Securing the aircraft is not just about screening who boards – it is also about ensuring that what boards is safe.

In a world of evolving threats, vigilance across every layer of the aviation system remains our strongest defence.

This article was originally published in the October edition of Security Journal UK. To read your FREE digital edition, click here.

https://securityjournaluk.com/aviation-security-securing-the-skies/

Published: 2025 10 03 12:22:36

Received: 2025 10 03 12:26:38

Feed: Security Journal UK

Source: Security Journal UK

Category: Security

Topic: Security

Views: 9